2.8.2022

A new self-neutralization tank serves in the dairy of Mlékárna Klatovy a.s.

In June, 2022, K&K TECHNOLOGY a.s. finished works on a self-neutralization tank in the dairy of Mlékárna Klatovy a.s. At present, the tank is subject to a trial operation.

In November, 2021, K&K TECHNOLOGY commenced construction of new buildings in the dairy premises of Mlékárna Klatovy. To comply with the investor´s requirements, a self-neutralization tank (hereinafter as the equalization tank) was built with the aim of eliminating the operational situations in which waste water was drained into the municipal sewerage system contrary to the sewer regulations. Today, the new equalization tank collects all waste water from the production process, equalizes pH and impurities, saves chemicals in the neutralization station, and increases effectiveness of the wastewater pre-treatment facility before discharge to the public sewer.

At first, waste water from the diary operation is drained into a pumping station, from which it is transferred into the 2100 m3 equalization tank. The enamelled tank has a reinforced-concrete bottom. To prevent the occurrence of putrefactive processes in waste water, there are three floating stirring aerators to stir and aerate the tank.

The waste water is discharged from the equalization tank to the self-neutralization station and further to a wastewater pre-treatment facility before being discharged into the public sewer.

17.6.2022

The first solar sludge drying facility in the Czech Republic was commissioned in Mariánské Lázně

On June 17th, 2022 the project of first solar sludge drying facility was handed over ceremoniously at WWTP Mariánské Lázně, with K&K TECHNOLOGY being the sludge drying technology supplier, SMP CZ a.s. being the contractor, and CHEVAK Cheb being the investor.

The solar sludge drying technology was installed in two halls providing a total useful area of 2200 m2. Natural sunlight is used for solar drying of sludge, while excess waste heat from the operation of the cogeneration unit can also be used to intensify drying.

The construction of solar drying facility is part of the prospective concept of sewage sludge treatment at a sludge center of the WWTP Cheb. The solar drying process at the WWTP of Mariánské Lázně will reduce the weight of dewatered sludge and in the future will make it possible to reduce the transport costs for transport of sludge for thermal treatment in the sludge center of WWTP Cheb. The solar dryer was installed partly on sludge fields which are available at the WWTP in a distance of about 300 m from the WWTP itself. Dewatered sludge is transported to the solar dryer by a transport mechanism and loaded into the dryer by a loader. The capacity of the dryer is 2000 t of dewatered sludge per year with a dry matter of about 20%, while the output dry matter of dried sludge is designed for up to 85%.

The main technological facility supplied by our company is the turning and disintegrating device to convey sludge from one side of the hall to the other. A ventilating system and turning device is controlled automatically. The solar dryer is equipped with a meteorological station connected to the control system.

.

More about solar drying facility in Mariánské Lázně

K&K TECHNOLOGY intesifies WWTP Klášterec nad Orlicí and sewage system

In December 2021, K&K TECHNOLOGY signed a contract for supply within the "Company for the City of Klášterec - Profistav+K&K". The company members - PROFISTAV and K&K TECHNOLOGY will implement the "Klášterec nad Orlicí" - WWTP Intensification and Sewage System Completion - 1st Phase" project together.

WWTP intesification for the capacity of 4200 EI will provide a sufficient capacity for wastewater treatment in the whole area in question with the legislative requirements and also for future connection of waste water from the Municipality of Pastviny and disposal of waste water conveyed from septic tanks and cesspools. The aim of the project is also to expand the existing sewerage system in the Town of Klášterec nad Orlicí in the localities of Lhotka, Zbudov, Čertovka, Hádka.

The new supply of the technology comprises a pumping station, raw pretreatment, bio-block and sludge management. Our work also includes complete electrical installation related to the new technology and proces control system with connetion to the control room.

The expected term of handing over the complete work to the investor is by the end of the year 2023.

30.11.2021

A pilot sewage sludge and biomass re-use project in the Czech Republic

On November 16th, 2021, the City of Písek and K&K TECHNOLOGY, the supplier of the technology, presented a sludge and biomass energy utilization station to project partners, representatives of institutions and organizations, and to the Ministry of the Environment represented by Richard Brabec, Minister.

The sludge and biomass energy utilization station is the first technological unit of its kind which was designed and implemented in the Czech Republic. At present, the technological unit is in a trial operation during which the optimal ratio of the individual fuel components is tested. It will process up to 3900 t of mechanically dewatered sludge per year and produce approximately 360 t of ash rich in phosphorus, potassium and other minerals suitable to be mixed in phosphate substrates. "I strongly believe and hope that the sludge and biomass energy utilization project will be successful and reproduced in the whole Czech Republic," said Richard Brabec, Minister for the Environment. According to the Mayoress, Eva Vanžurová, the City of Písek will be happy to share its experience with the operation of this unique plant with other cities.

The plant is semi-mobile and has been placed in the premises of the WWTP, which is why the whole process is ran in a sigle place. Dewatered sludge is conveyed from the existing belt filter press into an accumulation storage tank and further to the inlet part of a drying facility. Sludge drying takes place in a hot-air dryer designed with emphasis put on an automatic, simple but effective and sustainable operation. A hot-air boiler which burns dried sludge together with wooden chips is the source of thermal energy for drying. The final product of the entire process is an ash matter which is rich in minerals.

A significant benefit of this economically and operationally advantageous plant is also the minimization of impact of sewage sludge disposal on the environment.

More about the sludge and biomass energy utilization station.

06.09.2021

Pilot plant to verify efficiency for sludge thermal hydrolysis technologies at Prague CWWTP

In 2021, K&K TECHNOLOGY, joint-stock company, designed and supplied a sludge thermal hydrolysis model for the Central Wastewater Treatment Plant in Prague (CWWT). It cooperated on the project of the sludge management pilot plant model with the University of Chemistry and Technology Prague (VŠCHT).

At present, the installed sludge management model is testing different technological processes in the anaerobic treatment of the sludge produced in the CWWTP operation. The processes being tested enable anaerobic stabilization of individual sludge types without pre-treatment of with pre-treatment by means of the thermal hydrolysis system. On the basis of model testing, the most suitable technological system of sludge treatment will be recommended to increase biogas production and to achieve the highest dry matter concentration in the subsequently mechanically dewatered sludge.

The model management equipment is provided with a thermal reactor and a hydrolysis sludge tank, sludge accumulation tanks, pumps, a digestor, a storage tank, a sludge mechanical dewatering line, and the necessary measuring instruments with a control system.

Since its commissioning, the thermal hydrolisys model has been operated by the maintenance staff of Pražské vodovody a kanalizace under the management of the Faculty of Environmental Technololy of the University of Chemistry and Technology Prague. Pražská vodohospodářská společnost a.s. was the project investor.

04.06.2021

Wastewater pumping station in Litice after reconstruction

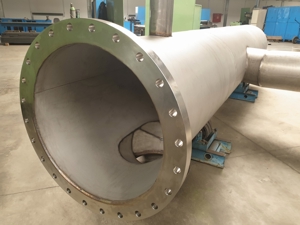

In May 2021, K&K TECHNOLOGY joint-stock company finished works on the mechanical and electrical parts of Litice pumping station (hereafter PS) for LK Pumpservices s.r.o. Our delivery included the complete equipment of pipelines such as DN 250, 500 inside and outside the PS including fittings, assembly, technological wiring, addition of an RM switchboard, production and assembly of a stainless staircase into the basement.

The purpose and the capacity of the PS remained the same, and the wastewater pumping technology has been modernized with the possibility of complete emptying.

30.04.2021

Reconstruction of Ráječek Water tank supplied by K&K TECHNOLOGY

In the period from May 2020 to April 2021, K&K TECHNOLOGY completed the reconstruction of the technological equipment in Ráječek Water tank (hereafter WT). The two-chamber WT with a capacity of 2x1500 m3 is used to hold drinking water for two consumption places in the town of Zábřeh na Moravě.

The subject of the investment project was the dismantling of the existing technological equipment, the complete delivery of new equipment, mainly made of stainless-steel materials, and minor structural modifications. Pipes, fittings, locksmith products, air conditioning, chamber coverings were replaced and the electrical technologies were reconstructed in the existing WT. Vodohospodářská zařízení Šumperk a.s. was the investor of the project.

15.1.2021

Raw water pumping station at WTP Homolka III in full operation

In December 2020, K&K TECHNOLOGY successfully completed a trial operation in the raw water pumping station at WTP Homolka, and handed over the finished work to the investor Vodárna Plzeň.

Our company´s delivery contained installation of raw water pumps and of the related large pipes of diameters up to DN 1000. There were also high voltage switchboards and transformers, RM1, DT 11 incl. automatic control system of technological processes (ASTPC) delivered and installed as part of electrical installation work.

14.10.2020

K&K TECHNOLOGY is the supplier of technology for WWTP Manětín

In April 2020, K&K TECHNOLOGY made a contract with its construction partners Porr a.s. and STAVMONTA spol s r.o. for the supply of a technology for the project titled Manětín - WWTP and Sewarage System. The project deals with the building of a new WWTP within new sewerage, pumping stations and discharge tanks for the Municipality of Manětín. The WWTP is designed as a mechanical and biological unit with a capacity of 1950 EI, and it will also receive collections from 14 neighbouring villages.

K&K TECHNOLOGY ensures complete delivery and assembly for machinery and electric equipment at Manětín Waste Water Treatment Plant and relevant pumping station.

The scheduled term of completion is July 2021.

23.6.2020

K&K TECHNOLOGY completed reconstruction of sludge and gas management at Tábor WWTP

K&K TECHNOLOGY, as a general contractor, completed the existing technological equipment of the final sludge treatment part at Tábor WWTP in order to increase its capacity, efficiency and operational reliability.

The existing storage tanks was used during sludge management reconstruction and it has been covered and modified into a digester tank - second stage to increase its volume functionality by 50%. The tank was also equipped with stirring, heating and K&K TECHNOLOGY product such as: digester cap, liquid pressure relief valve, biogas receiver, and helical heat exchanger. The digester tank can be used as a first-stage tank with sludge heating when potential repairs or shutdowns are needed.

The existing sludge thickening tank was rebuilt to a digested sludge storage tank.

Within the implementation, there were supplemented the necessary technololy of the gas compressor room, digester tank engine room and primary sludge pumping station incl. related modification of the electrical equipment and automatic control system of technological process.

30.4.2020

K&K TECHNOLOGY supplies and assembles pumping equipment for WTP HOMOLKA III.

K&K TECHNOLOGY currently participates as a subcontractor of SMP CZ in the reconstruction of raw water pumping equipment for Water Treatment Plant HOMOLKA III.

In the pumping station building, we have already installed raw water pumps and related large diameter pipes up to DN 1000. We have also installed new high voltage switchboards and transformers, RM1, DT11 incl. automatic control system of technological processes (ASTPC).

The reconstruction of raw water pumps at the pumping station takes place during operation with short shutdowns needed to have some pipeline section connected. Therefore, it´s planned into several stages with the completion date being scheduled for September 2020.

The pumping station is a part of the water treatment plant which ensures the supply of drinking water for more than 130 years in Pilsen.

17 January, 2020

Lime hydrate silo at Klenovec Water Treatment Plant

In December 2019, K&K TECHNOLOGY produced and supplied two steel lime hydrate silos to ProMinent Slovakia for Klenovec WTP.

The 30 m3 silos were designed for storing, preparation and dosing of lime hydrate as part of the WTP chemical management system. Their cylindrical design is terminated with a flat ceiling and a conical bottom, and it has its own supporting structure anchored to the concrete foundation. The silos are equipped with climbing ladders and safety railings on their tops. An air agitation and electric vibration technology is used to facilitate discharging the silo contents. To comply with the requirments, the silos were also equipped with knife gate valves, conveyors, dust filters, safety valves, control entrances, and limit probes.

The steel silos from K&K TECHNOLOGY are designed for outdoor applications to store bulk powder materials and granular mixtures. Besides their applications in the water management sector, they can also be used in agriculure, construction, food industry, and chemical plants.

11 December, 2019

Modernization of the open-plan water-management laboratory at the Czech Technical University

On November 28th, 2019, the Faculty of Civil Engineering (FCE) in Prague has ceremonially taken over the construction "CTU - FCE - Modernization of Open-Plan Water-Management Laboratory", to be used for teaching and research again.

K&K TECHNOLOGY together with SMP CZ, the general contractor, participated in the modernization. K&K TECHNOLOGY completed the main work on construction of the mechanical & technological facility. Further, our supply included reconstruction of pipelines, a measuring infrustructure installation, reconstruction of the existing hydraulic experimental trough, and replacement of a travelling crane.

The project implementation will enable FCE students to use the specialized laboratory again and thereby contribute to the development of their competencies, especially in the development models of water management structures and technologies.

21 October, 2019

FINNCHAIN scraper systems for multi-deck sedimentation tanks

As the use of land/ property needs to be efficient, sedimentation tanks at wastewater treatment plant can be built in multiple decks. The most common is double-deck, but it is not out of question to use even more. In these cases maintenance and repair can be challenging and expensive, so the operational reliability of the scraper system is extremely important.

Patented features developed by Finnchain guarantee not only a longer lifetime but also operational reliability which is crucial for scraper systems installed in multi-deck sedimentation tanks.

In BESOS WWTP (Aigues de Barcelona), there have been installed a total of 90 FINNCHAIN scraper systems. "We have installed FINNCHAIN scrapers in our plant for the removal of sludge of the settlers. This equipment is working correctly and complying with the function for which they were installed in 2006," told Manel Marquina Soler, Maintenance Manager EDAR.

K&K TECHNOLOGY a.s. has been appointed as FINNCHAIN sole representative in Czech Republic and Slovak Republic since AD 2002. For that time, K&K TECHNOLOGY has successfully supplied dozens of FINNCHAIN scraping systems.

More about FINNCHAIN scraper systems for multi-deck sedimentation tanks

27 June, 2019

Jindřichův Hradec WWTP aeration system modernization

In May 2019, K&K TECHNOLOGY a.s. handed over to the municipality of Jinřichův Hradec and put a reconstructed aeration system technology in the activation line at Jinřichův Hradec WWTP into trial operation.

The reconstruction of the activation line was carried out as the last phase of the complete reconstruction of the whole earation system, which included replacement of blowers and of the control system in the first phases.

K&K TECHNOLOGY supplied and installed a new pressure air supply line into the activation line and a new fine bubble aeration system into the nitrification tank and the sludge regeneration tank. At the same time, it modified the air supply management system for each tank and carried out rehabilitation and a new protective coating of the tank concrete walls.

The newly installed aeration elements are a more efficient technology and, moreover, they save electrical energy.

Replacing the air inlet pipe and aeration elements was part of a long-term project of reconstruction of one of the most important technological parts of the WWTP. The replacement project was quite challenging as the works had to be carried out during full operation without effectig the quality to the water treatment process.

5 June, 2019

K&K TECHNOLOGY supplies a new water tank for the town of Hrádek

In April 2019, company K&K TECHNOLOGY commenced earth works for the construction of a new water tank in the town of Hrádek in the place of an obsolete water tank. The current water tank accumulating 100 m3 is already unsatisfactory due to its one-day supply of water, therefore, the spring area of water sources will be strengthened with the construction of a new water tank. The building will serve primarily to accumulate 200 m3 and to distribute water to Hrádek by gravity, especially for the 750 people connected to a water main.

Above the water tanks and the valve chamber, a ground inlet facility has been built with a separate room to dose water treatment chemicals.

The construction is always done to secure continuous water supply to inhabitant and to operate the former water tank until the new water tank is commissioned.

In the following months, technological equipment of the water tank and connection of a new well will be carried out.The demolition of the former water tank and the landscaping of the building plot will be completed after the new water tank will have been put into operation.

28 February, 2019

K&K TECHNOLOGY has supplied a modern solution for a digester tank with an installed gas holder at WWTP Mariánské Lázně

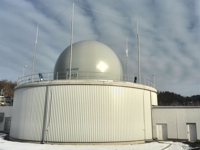

K&K TECHNOLOGY, joint-stock company, has reconstructed the sludge and gas management of the waste water treatment plant (WWTP) in the town of Mariánské Lázně, together with SMP CZ Praha, the reconstruction company in association titled "Společnost Mariánské Lázně - SMP - K&K". The reconstruction of the sludge and gas management at the WWTP began in April 2017 for Chevak Cheb as the investor, and was completed in January 2019.

K&K TECHNOLOGY has delivered a complete modern solution for the sludge and gas management. Originally anaerobic sludge stabilization had taken place in four digester tanks made of enamelled sheets. Because of damage, the tanks were disassembled and a new modern digester tank was built in their place. This option with an installed gas holder saves space in the WWTP facility.

The new digester tank of reinforced concrete with storage volume of 2,100 m3, inside diameter of 22 m, and height of 7,25 m, contains 780 m3 Sattler membrane gas holder anchored to the concrete ceiling. The digester is now precisely mixed by three mechanical tilting MSDH stirrers and its heating is provided by a heating coil inside the tank.

The vertical MSDH stirrers from K&K TECHNOLOGY own in-house production can be dismantled from the digester tank without interrupting its operation.

Besides the delivery of the technological equipment for the digester tank with the gas holder, K&K TECHNOLOGY supplied technology for storage tanks with recuperative heat exchangers, SGM engine room with a boiler room, and installations for processing - drying of biogas. The complete electrotechnical part was implemented within the contract including an automatic control system of technological processes.

11 November, 2018

K&K TECHNOLOGY is the technology supplier for the biological wastewater treatment plant (WWTP) in DEZA

In September 2018, K&K TECHNOLOGY signed a contract for a technological delivery within the association titled "Společnost ČOV DEZA-HT+KK+SM", with DEZA being the investor. The association members, namely HOCHTIEF CZ, K&K TECHNOLOGY and Stavební mechanizace - Servis, will jointly complete the "Wastewater Treatment Plant in DEZA" project.

The biological wastewater treatment plant (WWTP) reconstruction will enable to improve the technological process quality of sewage treatment, particularly focused on the disposal of cyanide and, therefore, water quality improving.

K&K TECHNOLOGY is primarily reconstructing the technological facility for the biological WWTP in DEZA plant. The newly supplied technology comprises a pumping station, machine racks, an equalization tank, a flotation facility, a biological treatment section including a secondary settling tank, a tertiary treatment section with a lamellar separator, two-stage pressure filtration, and sludge management.

Also, K&K TECHNOLOGY supplied complete electrical installations related to the new technology, a process control system and a security system.

The expected term of handing over the complete work to the investor is the beginning of 2020.

28 August, 2018

K&K TECHNOLOGY completed the reconstruction of Petrovičky WTP

In June 2018, K&K TECHNOLOGY completed the reconstruction of Petrovičky Water Treatment Plant (WTP) as the main water treatment plant in the urban are of Petrovičky and Makov (approx. 250 inhabitants). The WTP reconstruction also comprises new joining a well HV 3 to increase the capacity of the sources. The reconstruction was realized during full operation with no impact on water supply.

A new technological unit of water treatment plant was built in the former premises of the WTP to reduce the content of iron, manganese, arsenic and randon in water. Also, necessary civil works for the building were completed including the construction of a valve chamber at well HV3 and the construction of a new auxiliary tank for outlet water from pressure filter washing.

Pumps were replaced in all wells including new equipment for the valve chambers in the mouths of the bores, with the complete reconstruction of the electrical installations and installation of technological process control.

The water treatment plant was designed as an effective and safe water management insfrastructure, with its operation being fully automatic.

29 June, 2018

The technology of Sihoť Pumping Station was awarded the 1. prize of Zlatá AQUA

From 12 to 14 June 2018, K&K TECHNOLOGY attended the AQUA water management exhibition in Trenčín, where it obtained two awards.

On the first day of the exhibition, K&K TECHNOLOGY was awarded the first place in the Zlatá Aqua technology category and the second place for the "Modrý Akvadukt" exposition.

The Pumping Station Sihoť - Bratislava was awarded the 1st prize in the "Technology" category. The project titled "VZ Sihoť, rekonštrukcia ČS4 a TS4" comprised reconstruction of pumping station 4 and a pumping technology for five wells on Sihoť Island on the Danube River.

The capacity of the water resource at Sihoť is 900l/s, i.e. 28 mil. m3 per year. It supplies water to nearly a quarter of a million of people in Bratislava.

The main reason for this reconstruction was the depreciation and technical obsolescence of the technology which unacceptably increased the risk of failure of the water supply operation.

The project technology was supplied by K&K TECHNOLOGY a.s. with following parts: pumping station - the high-pressure part, the low-pressure part, well pumping technology.

23 March, 2018

K&K TECHNOLOGY a.s. supplied a technological solution for the Biogas station in Vyškov

At the end of the year 2017, K&K TECHNOLOGY finished the 1st phase of technological reconstruction of the Biogas station (BS) in Vyškov for the operator REBIOS spol. s r.o.

Two original propeller stirrers were repaired and two new long shaft propeller stirrers were supplied for the post-fermentor tank within the technological supply. To heat the post-fermentor tank contens, a new heating system was installed and the current gas holder was fitted with new safety elements and partial repairs of the current pipe fermenters were made.

At the same time, the current biofilter was reconstructed completely and completed with a new roof to reduce the bad smell spreading to the BS surroundings. The reconstruction was planned so that the period of the necessary outage in waste receipt could be as short as possible. After being supplied, the renewed technology by K&K TECHNOLOGY made the operation of the whole BS more effective including biogas, electrical and heat energy production while utilizing the energy potential of the incoming waste.

Biogas station Vyškov offers the possibility of disposal and utilization of biodegradable waste, animal by-products and other raw materials in its region.

19 February, 2018

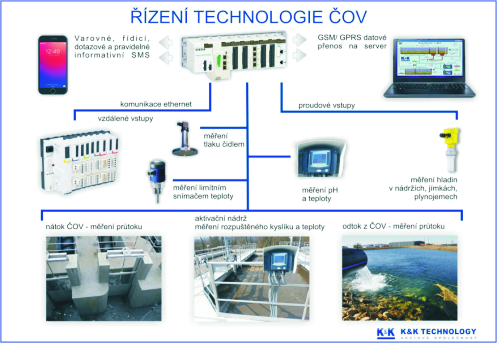

Operating info can be immediately visible through WWTP management control system

More effective operation of municipal waste water treatment plants (WWTP) is very important in terms of safety and operating cost savings. Therefore, every operator should consider investments into modern control systems which can transfer data from each section to control system and PC control room in WWTP. Our team of experts from K&K TECHNOLOGY can help you to control WWTP operation; our company has been an expert one for many years in water management and industrial automation.

Sophisticated constrol systems

The most modern way of control is via control systems that collect useful info from all operating units and evaluate it.

The following functions can be included in the delivery of WWTP automation systems:

- monitored quantity and level of inlet and outlet water pollution

- measurement of dissolved oxygen and temperature in activated sludge tank

- level monitoring in reservoirs, tanks, gas holders

- flocculant preparation and dosing management process

- sedimentation process management

- sludge discharge process management

- pH and temperature measurement

- complete technology operation analysis

- transmition of required data to the control room, sending warning, query or informative sms

Thus, you are informed promptly about all operating information that is an important factor for increased WWTP reliability. With online monitoring, you will also be able to get an overview of every equipment part or technological unit. This year, our company has also secured and assisted its clients with automation on the basis of their operating requirements in the sphere of water treatment plants, heating industry and management of packaging machines. Our expert team focused on control system designing, whether complete systems or parts thereof, will design the most suitable control systems and supply other related service.

20 December, 2017

K&K TECHNOLOGY has assembled technological equipment of biological line at Prague WWTP

Since 2017, K&K TECHNOLOGY has been assembling technological system PS02 - Pressure Air Piping within the biological line premises at Prague WWTP.

This is a stainless steel pipin system in a total lenght of 2,6 km. Stainless steel brackets made by K&K TECHNOLOGY are used to support the pipeline.

Furthermore, we have been providing assembly of low-speed stirrers (72 pcs),high-speed stirrers (28pcs), water gates, and check gates.

30 October, 2017

K&K TECHNOLOGY reconstructed the drinking water technology at Lužná pumping station

In October 2017, Lužná pumping station (PS) was commissioned and put into full operation for VaK Vsetín a.s., the investor. The subject of the delivery was replacement of the outdated PS technology. Our company K&K TECHNOLOGY was a General Contractor for the project, which consisted of mechanical, electrical and civil parts.

Four new 35 l/s capacity and 140 m head pumps were installed. The facility modification included new stainless steel pipelines and a hydraulic shock protection system. Complete new electrical installations were carried out incl. the delivery of switchgears, a motor generator of 275 kVA backup power and two 400 oil transformers. Our team specialzed in control system designing installed a new control system with data transfer to the central control station. The civil part consisted mainly in finishing the surface within the pumping station (wall tiling, paving, painting and finishing) and in new outside consolidated areas in front of the building.

When implementing the project, our company had to cope with and succeeded in meeting the investor´s requirement to replace the technololy during full PS operation with only short-therm shutdowns within hours.

3 July, 2017

K&K TECHNOLOGY supplies and assembles a sectional part of technological equipment at WWTP Praha

Since the beginning of the year 2017, K&K TECHNOLOGY has been supplying and assembling a sectional part of the technological equipment at WWTP Praha. Technology subdeliveries were realized in adequate quality according to the schedule for DEGREMONT WTE WASSERTECHNIK PRAHA - Main Contractor and Arko Technology - Subcontractor.

Our company has produced and assembled 204 pcs of stainless steel outflow channels for secondary sedimentation tanks. The assembly process is specific and more demanding due to the depth and covers of the tanks. For this time, only half of the total number of outflow channels is assembled.

Furthermore, K&K TECHNOLOGY provides assembly of floating matter pipes as part of object SO 09 and assembly of tensometric scale frames.

26 June, 2017

Reconstruction of digester tank at WWTP Klatovy

Based on a public tender, K&K TECHNOLOGY is the supplier of reconstruction for digester tank no. III. at WWTP Klatovy.

Before the reconstruction, the present concrete tank was operated as an open storage tank for digested sludge to be dewatered. After the reconstruction, it will be covered with a gastight steel cap and a long shaft MSDH stirrer for sludge homogenization will be installed inside the tank. Heating bodies will be installed to heat sludge and, finally, the pipes and technological equipment will be finished to use the tank for sludge anaerobic stabilization. The total storage capacity of the WWTP sludge management will be increased to 950 m3.

The expected term of completion is September 2017 with subsequent 6 months of trial operation.

1 April, 2017

Modernization of sludge and gas management solution at WWTP Mariánské Lázně

In March 2017, a contract for reconstruction of sludge and gas management was signed between CHEVAK Cheb and association "Společnost Mariánské Lázně - SMP - K&K" where K&K TECHNOLOGY, joint-stock company, is a participant.

K&K TECHNOLOGY has designed and will supply the modern sludge treatment and gas management including process control system. Intensification is based on the design of a new reactor with a gas holder installed on it. The 2193 m3 modern reactor will be built instead of the four existing obsolete digester tanks. The 780 m3 Sattler membrane gas holder will be anchored to the concrete ceiling of the reactor. The tank reactor of 22 m in inner diameter and 6,5 m in depth will be mixed precisely by three tilting vertical MSDH stirrers which will be installed on the top of the tank.

The electric control of the MSDH stirrer continually adapts equipment power via a frequency converter in dependence on the substrates supplied and on the individual need of mixing, spares the power set and protects against start-up surges. The motor with a gearbox and the tilting mechanism is designed for installation outside the tank. The shaft of the stirrer goes through a gas-tight ceiling bushing inside the tank.

The designed solution of modernization of the sludge and gas management will increase the efficiency of the anaerobic sludge stabilization process and energy utilization of the sludge generated by the WWTP operation

25 January, 2017

K&K TECHNOLOGY company announces the new business location

Dear Sirs and Madams,

it is our great pleasure to inform you that we have moved to our new offices on January, 25th. Our new address is Koldinova 672, 339 01 Klatovy II., Czech Republic.

In the correspondence or invoices please state our new address.

Our phone, fax numbers and e-mails will remain the same.

30 September, 2016

K&K TECHNOLOGY is a technology supplier for three WWTPs in the upper Nitra Region

In September 2016, K&K TECHNOLOGY signed a contract with one member of the association for the "WWTP North" project to supply technology for three WWTP´s. The "WWTP North" project addresses sewerage and waste water treatment in the Upper Nitra Region in Slovakia.

The subject of works in the Upper Nitra Region is construction of a 93-km logn sewerage system with 3744 sewer branches. The project also includes reconstruction of Partizanske WWTP for 30 thousand EI, Bánovce n. Bebravou WWTP for 26 thousand EI, and Topolčany WWTP for 58 thousand EI.

K&K TECHNOLOGY supplied complete reconstruction of the mechanical and electrical parts and of the process control system of the sludge and gas management for Partizánske WWTP, and reconstruction of the sludge and gas management mechanical and electrical parts and the process control system of the sand trap and storage tank for Bánovce n. Bebravou and Topolčany WWTP´s.

The scheduled deadline of the complete project is May 2017.

22 August, 2016

Reconstruction of sludge management and implementation of new gas management at Zlate Moravce WWTP

On August 22nd, Zlate Moravce WWTP was commissioned for a six-month trial operation. The technology part was completed by K&K TECHNOLOGY and handed over to the construction company - Vodohospodářské stavby a.s. Bratislava.

Our company participated in sludge management reconstruction and completion of the new gas management (mechanical - technological) part of Zlate Moravce WWTP within the following range:

- Technological equipment of the existing digester tank

- Technological equipment of a new digester tank

- Technological equipment of digester tank machine room incl. delivery of a screw heat exchanger

- Technological equipment of the compressor house used to stir the digester tak with biogas incl. delivery of The UTILE compressors

- Technological equipment of the cogeneration unit building incl. delivery of TEDOM cogeneration unit

- Construction of a double membrane gas holder incl. equipment of the gas holder engine room

- Technological equipment of the storage tank

- Delivery and assembly of absorption deulphurization device

- Delivery and assembly of biogas disposal 110 A device

- Equipment of the longitudinal sedimentation tanks

- Equipment of the circular secondary settling tanks

- Delivery and assembly of all shutters (both manual and electric)

- Technological equipment of the boiler room incl. the delivery of new VIADRUS boilers

27 July, 2016

Sludge drying plant at Karlovy Vary WWTP in trial operation

In May 2016, the trial operation of sludge drying unit at Karlovy Vary WWTP was commenced.

The plant is the first realization of low-temperature sludge drying in the Czech Republic. K&K TECHNOLOGY was the supplier of the technological equipment comprising pipe distribution and peripheral equipment needed to operate the sludge drier itself.

The subject of our delivery included the mechanical part and the control system. The delivery and assembly of the low-temperature drying machine was supplied independently by Spanish company STC Aqualogy. Our company directly manufactured and supplied a storage tank for dewatered sludge with volume of 30 m3 equipped with hydraulic travelling bottom and also rotating screw conveyer for dried sludge. The whole plant is designed as fully automatic with permanent supervision and designed capacity up to 6000 t of dewatered sludge per year.

The thermal drying system made by STC is based on hot air circulation at low temperature (air 80°C) in belt dryer. The drying process results in granulate with min. dry content of 90%. The granulate can be reused as a raw material to produce second-generation fuel. The sewage sludge will thus become a very interesting commodity within the philosophy of circular economy.

WWTP and BPS stirrer wins 1st place in the Golden Aqua contest

Joint-stock company K&K TECHNOLOGY participated in the 21st year of the AQUA Trenčín Water Management exhibition from 14 to 16 June 2016, and was awarded two prizes.

On 14 July 2016, joint-stock company K&K TECHNOLOGY was awarded 1st prize in the product category and 3rd prize for the best technology in the Golden Aqua contest at the AQUA exhibition. Both prizes were taken over by Ing. Jan Kutil and Ing. Josef Horejš, members of the K&K Technology Board.

The main prize in the product category was won by a long shaft stirrer for biogas plants and municipal and industrial wastewater treatment plants. The stirrer is used to mix liquid substrates of low to medium viscosity, homogenize substrates in tanks, and prevent the formation of sinking and floating layers.

The technology used in Trenčianske Stankovce WWTP was third in the best technology category. The concept of wastewater intensification and treatment at WWTP primarily involves intensification of the biological stage as the main part of the entire WWTP, having the primary effect on treated wastewater quality. Requirements for high reliability, lifetime and minimal maintenance needs were taken into account when designing the individual devices and equipment parts. The principal modernization solutions include the use of Invent hyberboloid stirrers in denitrification and nitrification tank homogenization.

1 June, 2016

K&K TECHNOLOGY reconstructs digester tanks at Žilina WWTP

In May 2016, K&K TECHNOLOGY concluded a contract for work for reconstruction of digester tank no. 2 at Žilina WWTP.

The reconstruction consists in complete replacement of digester tank technological equipment which is at the end of its lifetime period and rehabilitation of the tank inner surface in order to ensure tank water- and gas-tightness. The tank hydraulic mixing pump will also be replaced and the technology of collected sludge receipt and transfer into the digester tank will be completed. The reconstruction also includes installation of new measuring instruments and PLC to monitor and control the technological process of sludge management.

The aim of this project is to increase effectiveness and safety of the WWTP sludge and gas management.

The expected term of completion is October 2016.

16 February, 2016

K&K TECHNOLOGY a.s. is the general supplier and manufacturer of specilized equipment for biowaste processing

In February 2016, the 2nd phase of BGP Rybitví construction was put into trial operation for the investor Marius Pedersen a.s.

K&K TECHNOLOGY was the general supplier of the 2nd phase of Rybitví Biogas Plant with the aim to process biologically degradable waste including expired packed food. Our company manufactured and supplied specialized equipment for complete biologically degradable waste processing, i.e. package collecting, crushing and separating, and biowaste hygienization.

Collected biowaste incl. packages is unloaded into a steel storage tank with the capacity of 40 m3 and conveyed through a set of conveying and feeding screw conveyors from the tank bottom to an inclined screw conveyor and then to a separating facility. The separated biodegradable part of the waste is accumulated in a tank and then pumped into two pasteurization tanks for hygienization. Further, the hygienized suspension is dosed to the anaerobic tanks constructed in the 1st phase of the reconstruction.

Rybitví Biogas Plant is one of the modern biogas plants in the Czech Republic for complete biodegradable waste processing.

14 January, 2016

Reconstructed Púchov WWTP in one year trial operation

In January 2016, the one year trial operation of Púchov WWTP was commenced. K&K TECHNOLOGY was the general supplier of the technological part for the Púchov WWTP reconstruction project. The delivery of our company included reconstruction of the technological equipment for mechanical pre-treatment, biological treatment, sludge and gas management including electrical part and automated control system with remote control.

The biological phase was designed as an activation process starting with denitrification and resulting in oxic zones to secure nitrification. As part of the sludge and gas management reconstruction, in addition to other things, a double membrane gas holder with the capacity of 260 m3 was installed. The produced biogas will be used in the newly installed cogeneration unit generating electric power.

The project titled “Púchov District Water Supply and Sewage System - Phase I” increased the proportion of waste water treatment at Púchov WWTP to 30 000 EI together with anaerobic sludge stabilization and extended the sewerage system in the agglomeration of Púchov - Dolné Kočkovce, Dohňany, Púchov, a Střeženice. According to the applicable legal standards of the Slovak Republic, waste water collection and treatment at Púchov WWTP will have a positive impact on the environment, especially on the quality of Váh River surface water.

26 November, 2015

The 9th conference "ANAEROBIE" was held in Klatovy

K&K TECHNOLOGY together with the CZWA Sludge and Waste Expert Group and in coordination with the Association of Wastewater Treatment Experts of the Slovak Republic was the organizer of the 9th Year of the “ANAEROBIE” expert conference held in October 21-22, 2015 in Klatovy.

The conference concerning the anaerobic technologies took place in the K&K TECHNOLOGY administrative building and was attended by business partners and 150 participants of water treatment operators, designers, representatives of universities, state agencies and all current and future operators of the anaerobic technologies.

The lectures focused on the trends in developing and achieving the current knowledge of the anaerobic treatment processes, experience in the operation of sludge management and energy recovery from sludge that contributes considerably to WWTP energy self-sufficiency.

K&K TECHNOLOGY participated in the lectures concerning experience and current knowledge in sludge and gas management designing and operating for the last 25 years and in the modern solutions of fermentation tanks and the issue of foam formation in digester tanks, and disposal of sludge via drying or combustion.

20 October, 2015

Choceň Water treatment plant in trial operation

In the period 2014 - 2015, K&K TECHNOLOGY, member of an association of companies, took part in the “Choceň, CH -1 Water Treatment Plant” project. Our company K&K TECHNOLOGY was the supplier of technology for engineering part, electric part and automated control system with remote control.

The function of the newly designed construction is mainly to ensure treatment of groundwater from the newly exploited deep well to meet the legislative requirements to provide drinking water quality for drinking water supply. The project provides drinking water supply for 9340 inhabitants. Two parallel pressure filters Culligan to dose sodium hypochlorite with capacity treatment 35 l/s were installed. The water treatment plant is designed to be fully automatic with occasional supervision and chemicals preparation and filling.

The new water treatment plant was started up for trial operation in October 2015.

3 August, 2015

K&K TECHNOLOGY carries out the second phase of implementation

in Biogas station - Rybitví

In July 2015, K&K TECHNOLOGY made a contract for work for the implementation of the 2nd phase of processing other substrates. The 2nd phase is being built with the aim of maximum power production while using the power capacity of sludge processed by the nearby waste water treatment plants and receiving biodegradable waste subject to hygienization.

Within the 2nd phase, K&K TECHNOLOGY supplies specialized equipment to collect and process biodegradable waste.

The expected term of completion of the work is by the end of the year 2015. Trial operation is scheduled to commence at the beginning of the year 2016.

13 August, 2015

![]()

Educational activity – “Training of Welders of Steel Structures and Technological Pipelines according to EN 287-1”, Reg. No. CZ.1.04/1.1.00/C3.00001

From 24 to 28 August 2015, K&K TECHNOLOGY will organize an educational activity titled “Training of Welders of Steel Structures and Technological Pipelines according to EN 287-1”, which will be attended by 8 employees, within the National Individual Project “Support of Professional Education for Employees”, Reg. No. CZ.1.04./1.1.00/C3.00001.

The project titled “Support of Professional Education for Employees”, Reg. No. CZ.1.04/1.1.00/C3.00001, is co-financed by the European Social Fund and from the state budget of the Czech Republic.

16 July, 2015

Železná Ruda WTP in trial operation

In May 2015, Water Treatment Plant was handed over to the project general contractor Lesní stavby Nýrsko for trial operation. Water treatment plant intensification was commenced in January 2015.

The intensification includes a new filtration unit based on the principle of two-stage coagulation pressure filtration including pressure measurement system to provide for WTP automatic control depending on raw water quality.

K&K TECHNOLOGY supplied technology such as UV filter, pumps, piping system incl. valves, compressors, measuring system, and automatic control system.

New installation of WTP with capacity of 12 l/s is designed to ensure drinking water supply to the Town of Železná Ruda in sufficient quality and quantity.

18 June, 2015

The new generation of helical heat exchanger

During the Vodovody - kanalizace 2015 exhibition, the new generation of helical heat exchanger was launched using an innovative production and material technology.

The helical heat exchanger of K&K TECHNOLOGY a.s. is simple equipment to be used for indirect warm-water heating of mixed sludge and to keep process temperature of anaerobic sludge stabilisation in WWTP digesters and biogas plant fermentors.

The product is easy to fit in place and to handle while being cleaned. For access to the screw heat area, the helical heat exchanger is fitted with a small crane to handle the cover. The big advantage is easy replacement of the heat exchanger screw if it fails.

Screw heat exchanger TVVK 6 was promoted at the 19th Vodovody - kanalizace Water Management Exhibition.

Through a cut-out in the shell, visitors could see the auger to satisfy themselves of the improvement of the product properties.

For more information, please visit the product page – helical heat exchanger.

26 March, 2015

Intensification of gas management at WWTP Sokolov

In January 2015, K&K TECHNOLOGY handed over the modernized gas management as a part of WWTP SOKOLOV intensification, Phase I. The former wet gasholder was reconstructed for dry seal type incl. TECON membrane with the capacity of 450 m3 within the delivery for ARKO TECHNOLOGY. A new building of gasholder engine room was equipped with a product line such as water seal, water drain and water reservoir supplied by K&K TECHNOLOGY. The former gas compressor plant was fitted with two UTILE gas compressors.

20 January, 2015

Extension of sludge management at Karlovy Vary WWTP

From May to December 2014, K&K TECHNOLOGY a.s. supplied and installed a third decanter centrifuge by Centrivit to dewater digested sludge at the Karlovy Vary WWTP.

The centrifuge was installed including all accessories, new supply piping for dewatered sludge to containers, and an automatic operation control system. The order also covered customization of the valve chamber equipment for sludge withdrawal from the digested sludge homogenization tank.

The newly installed centrifuge will increase the digested sludge processing capacity by 22m3 per hour.

28 November, 2014

Benešov WWTP in trial operation

At the end of November, K&K TECHNOLOGY handed over the complete technology of the Benešov WWTP to the project general contractor POHL CZ,a.s. for trial operation. The investment project of the town of Benešov was aimed at i